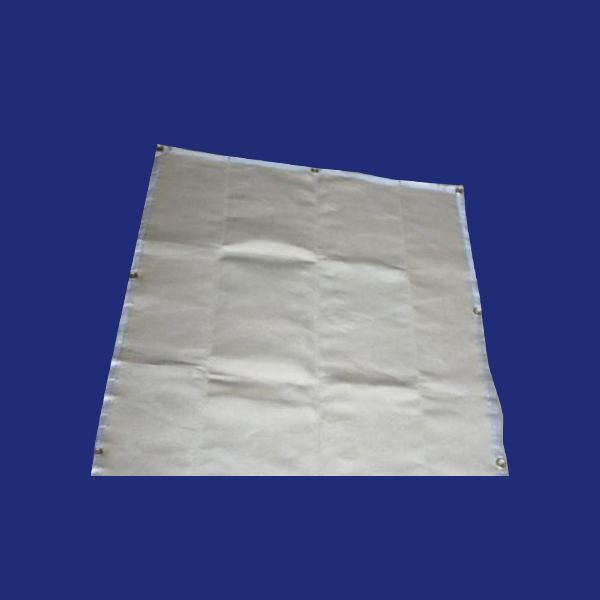

High Silica fiberglass fabrics

High silica fiberglass fabric can be effectively used at steady state temperatures to 1000 degree -1700 degree without deterioration of formation of cristobalite structure. The silica fabric has been specially developed to use in the applications to protect extreme temperature environment. They also have excellent chemical resistance and electrical insulation properties.

96% High Silica Cloth can be used efficiently at stable altitudes up to 1000 degrees-1700 degrees without cristobalite building decay. The silica fabric has been created specifically for use in apps to safeguard the atmosphere of intense temperatures. They also have outstanding chemical resistance and characteristics of electrical insulation.

DSZ 1.3 is a silica material with a high weight of 96%. DSZ1.3 is great for opposition to very elevated temperatures and flame. Isolation ##s, padding, lagging, cooking cover, flame shield and other strong smoke monitoring equipment are used. SL 1200 is appropriate for elastomer and polymer differential layer.

96% High Silica Cloth Manufacturer can be used efficiently at stable altitudes up to 1000 degrees-1700 degrees without cristobalite building decay. The silica fabric has been created specifically for use in apps to safeguard the atmosphere of intense temperatures. They also have outstanding chemical resistance and characteristics of electrical insulation.

DSZ 1.3 is a silica material with a high weight of 96%. DSZ1.3 is great for opposition to very elevated temperatures and flame. Isolation ##s, padding, lagging, welding blanket, fire curtain and other strong fire control system are used. SL 1200 is appropriate for elastomer and polymer differential layer.

The composition of 96% High Silica Cloth Manufacturer in Mumbai is over 96%. Are you suggesting this Silica Fiberglass fabric to operate in 1000? And the operating temperature is 1200? Melting limit is 1700?

Silica fabric is an optimal material for heat insulation and electrical insulation at elevated temperatures. High Silica Temperature Resistance Fiberglass fabric has wide-ranging apps that are generally used in metallurgy, rocket construction, aircraft construction, shipbuilding, automotive industry, nuclear power and computer construction.

Non-pollution: Silica Cloth is safe compared with Asbestos Cloth and Ceramic Fiber Cloth.

High resistance to temperature: is the working temperature 1000? That’s 1740 melting point? Temperature suggested is 950?

Small Thermal Shrinkage: Low Electrical Conductivity after Preshrunk Processing, Silica Fabrics Have Very Little Loss On Ignition & Linear Thermal Shrinkage: Less Metallic Ion and Super Electrical Insulation after Acid Treatment from 96% High Silica Cloth Manufacturer in Chennai

| PROPERTY DATA | |||

| (Metric) | (English) | Test methods | |

| Weave | 12H Satin | 12H Satin | |

| Construction | |||

| Warp | 19 ± 1 ends/cm | 48 ± 3 ends/inch | ASTM D 3775-96 |

| Weft | 14 ± 1 picks/cm | 33 ± 3 picks/inch | ASTM D 3775-96 |

| Weight | 1200 ± 150 g/m2 | 36 ± 4.4 oz/yd2 | ASTM D3776-96 |

| Thickness | 1.5 ± 0.08 mm | 0.06 ± 0.003 inch | ASTM D1777-96 |

| Standard width | 92.0 ± 1 cm | 36 ± 0.39 inch | ASTM D3776-96 |

| 100.0± 1 cm | 39± 0.39 inch | ||

| Tensile strength | |||

| Warp | 800 N/25 mm | 92 lbf/inch | ASTM D5034-95 |

| Weft | 500 N/25 mm | 57 lbf/inch | ASTM D5034-95 |

| Temp resistance Peak Temp. |

10000C 15000C |

18300F 27500F |

|

| tyle no. | weave | weight g/m2 oz/yd |

thickness mm inch |

sio2 content |

|---|---|---|---|---|

| DSZ 6.4 | 8H Satin | 640 18 | 0.76 0.03 | 96% |

| DSZ 1.3 | 12H Satin | 1250 36 | 1.40 0.055 | 96% |

Place of Origin: Ahmedabad, Gujarat, India

Brand Name: Signature by DSZ

Weight: 1250g/m2

Weave Type: Twill Woven

Yarn Type: E-Glass

Alkali Content: Alkali Free

Standing Temperature: 1700 degree

Width: 914mm

Packaging & Delivery Packaging Details:

Rolls packed in cartons loaded on pallets

Delivery Detail:

Within 0 days